Advantages:

1. Advanced professional equipment ensures good quality assurance, safety, non-toxic, and good sealing.

2. Strong toughness and firmness, and professional testing can detect their corresponding toughness and firmness.

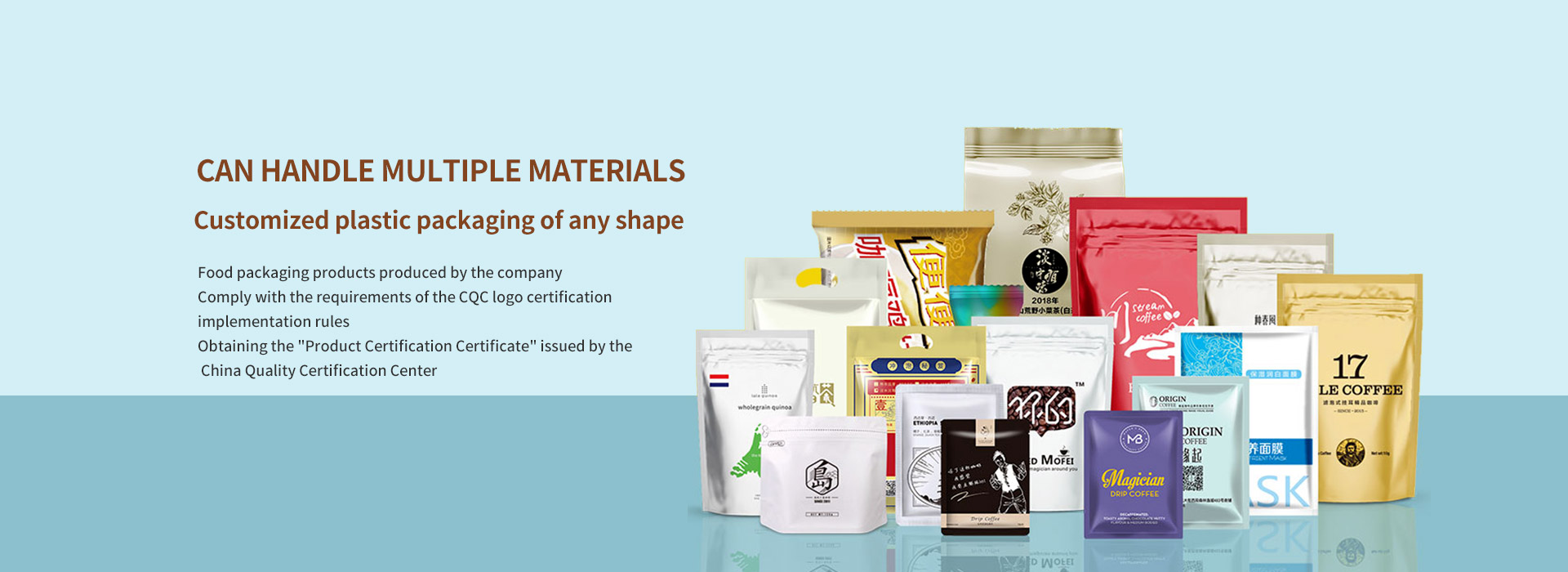

3. Custom printing: It can be printed according to customer requirements, and the exquisite outer packaging image can quickly attract consumers' attention, which is conducive to improving product image and competitiveness.

4. Professional manufacturer with over 20 years of production experience and a stable customer base.

5. The "self inspection and quarantine unit" approved by the Qingdao Entry Exit Inspection and Quarantine Bureau (registration number: S370209).

6. QS production license certification number Lu XK16-204-04783 and ISO9001 and ISO14001 certifications.

7. A complete set of laboratory and experimental equipment provides you with a one-stop solution.

8. Perfect after-sales service allows you to worry free.

Collaboration process:

1. Consulting/Selecting Products

2. Determine cooperation intention

3. Free production and provision of samples

4. Customer confirms our sample

5. Contract payment

6. Produce finished products according to samples

7. Customer acceptance

8. High quality after-sales service

Production process:

1. Office center, packaging product preliminary design, layout, scheduling, material ordering, etc

2. The production department's dust-free printing workshop provides you with fast and stable printing, using environmentally friendly and non-toxic benzene free inks.

3. Production department dust-free composite workshop: composite the printed single-layer materials into the required number of layers, and roll the composite materials into the curing room. The composite glue used is edible glue.

4. Production Department Dust free Cutting Workshop: Cut the excess part of the printed, composite, and matured material rolls into the range you need, with an error of less than 0.8mm.

At present, our company is equipped with 1050mm high-speed electronic axis printing machine, high-speed solvent-free composite machine, 700mm high-speed octagonal sealing (square bottom bag) bag making machine, 1300mm high-speed slitting machine, Japanese Taiyang inspection machine, three-layer co extrusion blow molding machine, and other equipment. At the same time, we are equipped with complete product physical and chemical performance inspection equipment such as gas chromatograph, electronic tensile testing machine, friction coefficient meter, pendulum impact resistance meter, and back pressure high-temperature steaming machine. Annual production of 3000 tons of food grade packaging bags and 5000 tons of polyethylene film.

1. Advanced professional equipment ensures good quality assurance, safety, non-toxic, and good sealing.

2. Strong toughness and firmness, and professional testing can detect their corresponding toughness and firmness.

3. Custom printing: It can be printed according to customer requirements, and the exquisite outer packaging image can quickly attract consumers' attention, which is conducive to improving product image and competitiveness.

4. Professional manufacturer with over 20 years of production experience and a stable customer base.

5. The "self inspection and quarantine unit" approved by the Qingdao Entry Exit Inspection and Quarantine Bureau (registration number: S370209).

6. QS production license certification number Lu XK16-204-04783 and ISO9001 and ISO14001 certifications.

7. A complete set of laboratory and experimental equipment provides you with a one-stop solution.

8. Perfect after-sales service allows you to worry free.

Collaboration process:

1. Consulting/Selecting Products

2. Determine cooperation intention

3. Free production and provision of samples

4. Customer confirms our sample

5. Contract payment

6. Produce finished products according to samples

7. Customer acceptance

8. High quality after-sales service

Production process:

1. Office center, packaging product preliminary design, layout, scheduling, material ordering, etc

2. The production department's dust-free printing workshop provides you with fast and stable printing, using environmentally friendly and non-toxic benzene free inks.

3. Production department dust-free composite workshop: composite the printed single-layer materials into the required number of layers, and roll the composite materials into the curing room. The composite glue used is edible glue.

4. Production Department Dust free Cutting Workshop: Cut the excess part of the printed, composite, and matured material rolls into the range you need, with an error of less than 0.8mm.

At present, our company is equipped with 1050mm high-speed electronic axis printing machine, high-speed solvent-free composite machine, 700mm high-speed octagonal sealing (square bottom bag) bag making machine, 1300mm high-speed slitting machine, Japanese Taiyang inspection machine, three-layer co extrusion blow molding machine, and other equipment. At the same time, we are equipped with complete product physical and chemical performance inspection equipment such as gas chromatograph, electronic tensile testing machine, friction coefficient meter, pendulum impact resistance meter, and back pressure high-temperature steaming machine. Annual production of 3000 tons of food grade packaging bags and 5000 tons of polyethylene film.

{{json5034.length}}